that are operated based on first-in, first-out basis

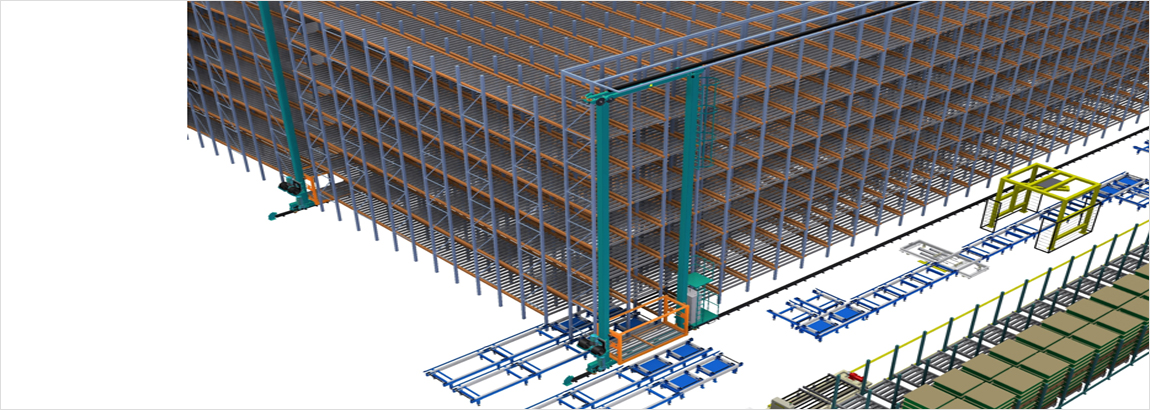

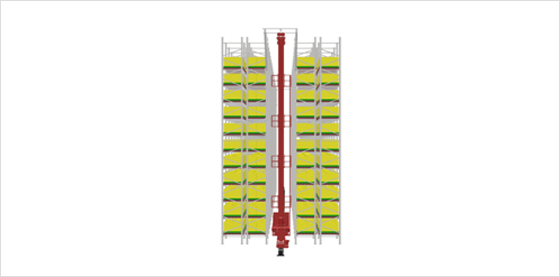

An automated storage and retrieval system

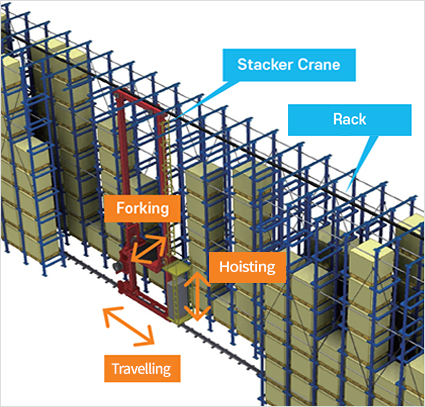

transfers products or cargo using a stacker crane

without the intervention of people, stores them on the racks,

and inputs/outputs products with WMS control

when orders are placed to meet customer needs.

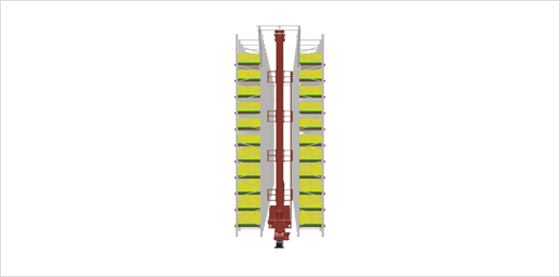

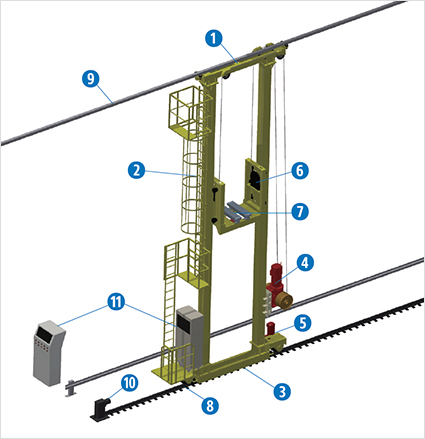

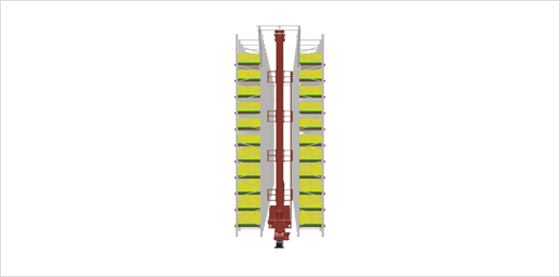

| NO. | 내용 |

|---|---|

| 1 | Upper frame |

| 2 | Mast |

| 3 | Lower frame |

| 4 | Hoisting equipment |

| 5 | Travelling equipment |

| 6 | Carriage |

| 7 | Fork |

| 8 | Lower rail |

| 9 | Upper rail |

| 10 | Stopper |

| 11 | Controller (ground and air) |

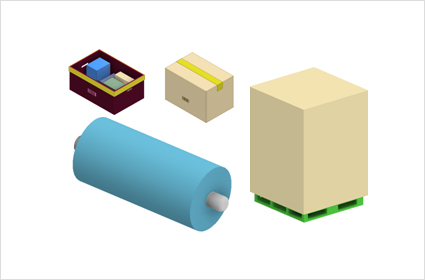

We are capable of designing to meet product form.

We are dedicated to customized design of various forms

including general pallet, boxes and cases.

We are capable of designing

to meet product form.

We are dedicated to customized design

of various forms including general palettes,

boxes and cases.

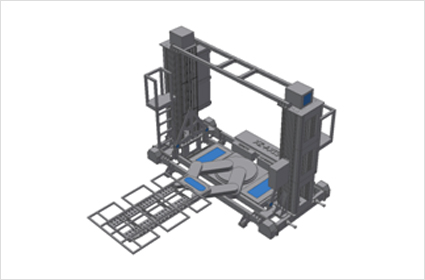

It is a stacker crane for clean room.

This model minimizes dust generation from upper and lower rails.

It is suitable below 1000 class.

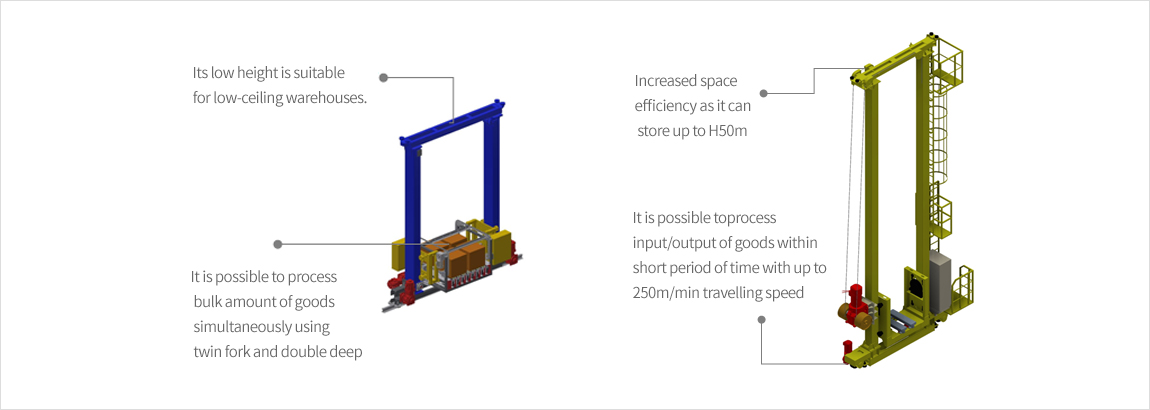

Stacker cranes, operated with diverse numbers of forks (1 to 4) and desired speed are available by considering the weight

and cycle time of various products such as mini load that transfers light-weight products below 50kg.

| Division | Light-weight model | Heavy-weight | Ultra Heavy-weight | |

|---|---|---|---|---|

| Handling load | 10kg ~ 500kg | 1,000kg ~ 3,000kg | 1,500kg | |

| Speed | Travelling | 60m/min ~ 300m/min | 60m/min ~ 250m/min | Max. 120m/min |

| Hoisting | 30m/min ~ 60m/min | 30m/min ~ 60m/min | Max. 30m/min | |

| Forking | 20m/min ~ 60m/min | 20m/min ~ 60m/min | Max. 30m/min | |

| Height | 2.5m ~ 12m | 15m ~ 50m | 10m ~ 27m | |