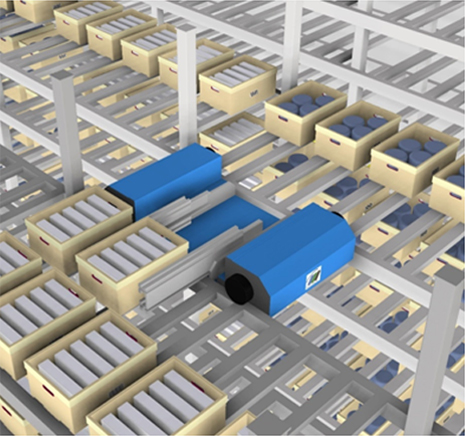

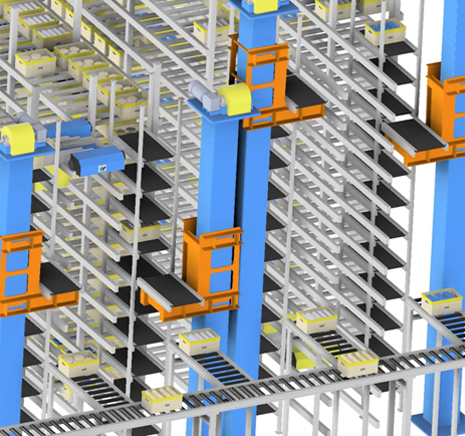

This is a system where multiple shuttle cars installed in each column of storage rack move in the aisle between racks

and picks boxed products (totes, trays, cartons) and ship to GTP (Goods to Person) work station via lifter

and conveyor to process order.

Products

Picking & Sorting System

>

Products >

Composition of system

Shuttle Car

Lifter

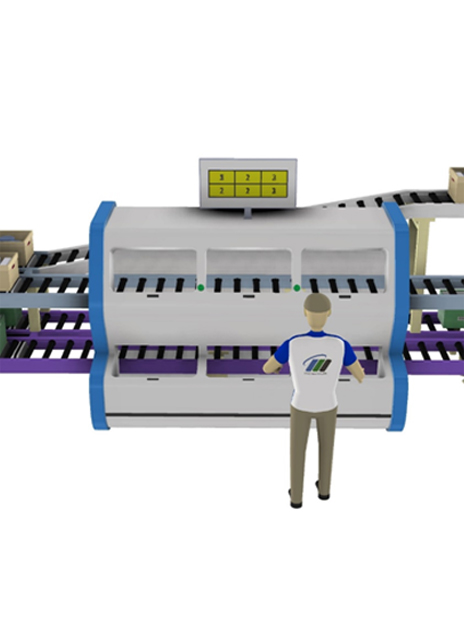

GTP Work Station

Conveyor

Shuttle Car Specifications

| Load | |

|---|---|

| Loading weight | Average 30KG, Max 50KG |

| Type | Totes, Trays, Cartons |

| Loading Dimensions | 150*150*150mm ~ 800*600*600mm |

| Speed and performace | |

|---|---|

| Speed | Max. 4m/s |

| Acceleration | Max. 2m/s² |

| Positioning accuracy | ±3mm |

| Capa per single machine | 100 cases/hr |

| Power Supply | |

|---|---|

| Walking motor power | 750w |

Lifter Specifications

| Cargo Lifter | |

|---|---|

| Rated load | 100kg |

| Effective storke | 5,030mm |

| Working stroke | 4,875mm |

| Speed | 3m/s |

| Acceleration | 7m/s² |

| Motor power | 4.4kW |

| Tray Specification | 1,080*642mm |

| Driving medium | Synchronous belt |

GTP Station Specifications

| GTP Station | |

|---|---|

| Size | 2,710*1,600*2,100mm |

| Structure Type | Double Layer : upper Source Box and lower order box |

| Transporter | ≥ 600 cases / hour |

| Roller Drive | 0.6 m/s |

| Weighing accuracy | ± 50g |

| Load Weight | 35kg per reservoir |

| Handling box specification |

300mm ≤ L ≤ 600mm

300mm ≤ W ≤ 400mm

150mm ≤ H ≤ 320mm

|

| Control Cabinet | |

|---|---|

| Size | 600*250*1,100mm |

| Structure Type | Independent cabinet, standing mode |

| Transporter | ≥ 600 cases / hour |

| power supply | 220V |

| Output voltage | 24V, 220V |

| Controller | Siemens PLC |

| Electric roller | 24V, ASI control mode |

·The above can be changed according to the customer's request

Introduction Environment and Benefits

Buffer, Sequencing Function

- - Buffer function of boxed products

- - Can process in the order based on sequencing function that sequentially accepts and releases boxes

High-density Storage

- - High-density storage of boxed products offer high storage density for the area

High Productivity

- - High order processing ability among various GTP solutions

- - Suitable for logistics environment such as distribution centers that handle high level of volume

Excellent Response to SKU Expansion

- - Flexible response to SKU change and expansion due to the capability of managing and changing SKU for each storage cell

Flexible Expansion

- - Capable of additional input of shuttle when processing volume is increased

- - Capable of extending modules such as racks, shuttles, lifters, etc.

Easy Maintenance

- - Fast response to shuttle malfunctioning or maintenance due to transfer to designated maintenance station for repairs via shuttle transfer lifter